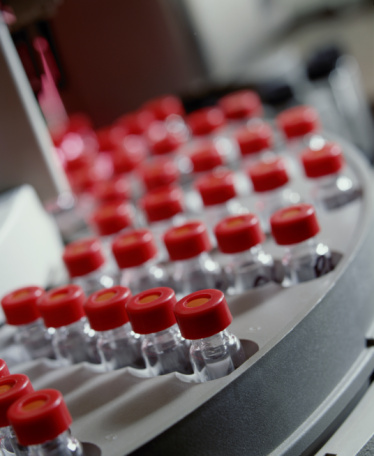

Degenkolb Engineers provided conceptual design, detailed nonlinear analysis and construction documents for two base isolated platforms for a new biotechnology fill-finish line located within an existing facility. The platforms used WorkSafe Technologies patented Ball-n-Cone seismic isolators and were designed to accommodate the displacements expected during the Maximum Considered Earthquake. The design was validated by conducting nonlinear time history analysis. The platforms were constructed of stainless steel components and a specially designed moat was developed and tested to meet strict FDA cleanliness requirements. Design, fabrication and installation were completed within a tight time frame of five months to meet the owner’s overall project schedule.

A seismic risk analysis indicated that a large earthquake would significantly damage the two new fill-finish lines being installed within the new fill-finish facility. The lead time to replace the fill-finish lines was 18 months. The owner determined that 18 months of downtime was not acceptable as it would significantly impact their business operations. The owner request that the design team develop a method to protect the fill-finish lines from the damaging effects of an earthquake. After reviewing multiple options it was decided that installing the fill-finish lines on seismically isolated platforms was th most cost effective method of protection. The ball-n-cone isolated platforms limit the accelerations imparted to the equipment due to earthquake ground shaking to approximately 20% of gravity, protecting the equipment from damage.

Features:

Base isolation. Performance based engineering.

Benefits:

Immediate Occupancy performance.